Mechanical Tube & Pipe, Structure Tube, Seamless Mechanical Tubing, Seamless Structure Tube,

Precision Mechanical Tube, Seamless Precision Tube

Standard: ASTM A53, ASTM A106, ASTM A519, ASTM A500, ASTM A252,

JIS G3441/G3445, EN 10210/10297

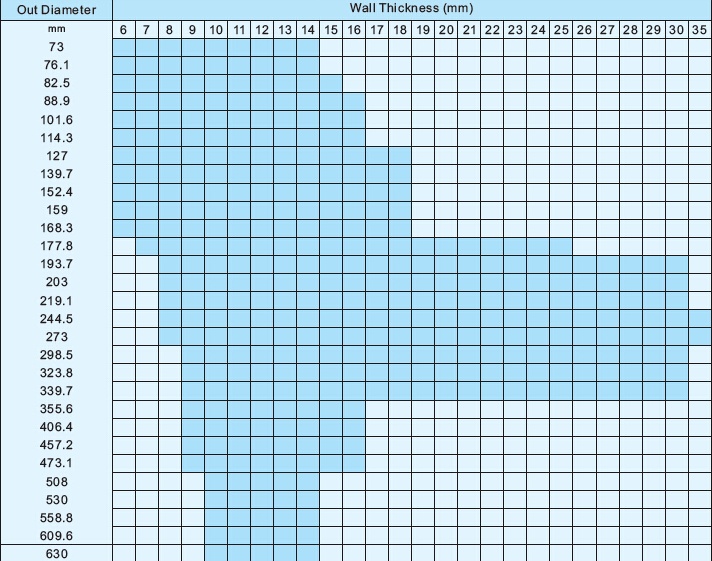

Size: OD: 10.3-762mm

WT: 6-35mm

Length: 5.8/6/11.8/12m

Application: Used in the general structure and the mechanism, including construction, machinery, transportation, aviation, petroleum mining and each kind of structural tubes

Seamless mechanical tubing: ASTM A519

DOM mechanical tubing: ASTM A513 T5

ERW mechanical tubing: ASTM A513 T1 or T2

Mechanical Tubing: Tubing used in mechanical and light structural applications. Mechanical pipe & tube is manufactured to meet specific end-use requirements, specifications, tolerances and chemical compositions. This results in a more specific uniformity of performance across the entire pipeline compared to standard pipes. While mechanical pipes can be produced to standard specifications upon request, they are usually produced to "typical" properties which focus on yield strength for a specific size and wall thickness. In some severely formed applications, the yield strength may not even be specified, and mechanical tubes are produced to be "fit for service." Mechanical tubing covers a wide range of structural and non-structural applications. Cold drawn or cold rolled precision seamless steel tubes are used to manufacture mechanical structures and hydraulic equipment, which can greatly save machining time and improve material utilization and product quality.

Application of mechanical tubing:

Solar Racking

Agricultural and dairy products

Greenhouse structures and equipment

Playground and recreational equipment

Conveyor rollers

Carports and metal buildings

Trailers

Appliances

Canopies and Shade Structures

Satellite dish supports

Vinyl stiffening tubes

Miscellaneous product applications

Structural Tubing: Tubing used for structural applications. Standard strength requirements of the tube help dictate applications for which certain tubing is most appropriate. Structural tube is often referred to as hollow structural sections or HSS, are available in round, square and rectangular shapes.

Application of Structural Tubing:

Buildings

Bridges

Towers

Cranes

Sign supports and poles

Off-shore production and drilling platforms

Roll-over protective structures (ROPS)

Chemical composition and mechanical properties

|

Standard |

Grade |

Chemical composition(%) |

Mechanical properties |

||||||

| C |

Si |

Mn |

P | S |

Tensile Strength(Mpa) |

Yield Strength(Mpa) |

Elongation(%) |

||

|

DN1629 |

St37 |

≤0.17 |

- | - |

≤0.04 |

≤0.04 |

350-480 |

≥235 |

≥25 |

|

St44 |

≤0.21 |

- | - |

≤0.04 |

≤0.04 |

420-550 |

≥275 |

≥21 |

|

|

St52 |

≤0.22 |

≤0.55 |

≤1.60 |

≤0.04 |

≤0.035 |

500-650 |

≥355 |

≥21 |

|

Cold drawn seamless mechanical tubing---Diameter Tolerances

|

OD Size Range Inches,Inclusive |

WallPercent of OD |

OD Inches |

ID Inches |

Quenched&TemperedOD & ID ± Inches |

OD Size Range mm ,Inclusive |

WallPercent of OD |

OD Inches |

ID Inches |

Quenched&TemperedOD & ID ± mm |

||||

|

Over |

Under |

Over |

Under |

Over |

Under |

Over |

Under |

||||||

|

0.500-1.699 1.700-2.099 2.100-2.499 |

All All All |

.005 .006 .007 |

.000 .000 .000 |

.000 .000 .000 |

.005 .006 .007 |

.015 .020 .023 |

12.70- 43.16 43.17- 53.32 53.33- 63.48 |

All All All |

0.13 0.15 0.18 |

0.00 0.00 0.00 |

0.00 0.00 0.00 |

0.13 0.15 0.18 |

0.38 0.51 0.58 |

|

2.500-2.899 2.900-3.299 3.300-3.699 3.700-4.099 |

All All All All |

.008 .009 .010 .011 |

.000 .000 .000 .000 |

.000 .000 .000 .000 |

.008 .009 .010 .011 |

.025 .028 .030 .033 |

63.49- 73.64 73.65- 83.80 83.81- 93.96 93.97-104.12 |

All All All All |

0.20 0.23 0.25 0.28 |

0.00 0.00 0.00 0.00 |

0.00 0.00 0.00 0.00 |

0.20 0.23 0.25 0.28 |

0.64 0.71 0.76 0.84 |

|

4.100-4.499 4.500-4.899 4.900-5.299 5.300-5.549 |

All All All All |

.012 .013 .014 .015 |

.000 .000 .000 .000 |

.000 .000 .000 .000 |

.012 .013 .014 .015 |

.036 .038 .041 .044 |

104.13-114.28 114.29-124.44 124.45-134.60 134.61-140.95 |

All All All All |

0.30 0.33 0.36 0.38 |

0.00 0.00 0.00 0.00 |

0.00 0.00 0.00 0.00 |

0.30 0.33 0.36 0.38 |

0.91 0.97 1.04 1.12 |

|

5.550-5.999 |

Under 6 6 to 71/2Over 71/2 |

.010 .009 .018 |

.010 .009 .000 |

.010 .009 .009 |

.010 .009 .009 |

.047 .047 .047 |

140.96-152.38 |

Under 6 6 to 71/2Over 71/2 |

0.25 0.23 0.46 |

0.25 0.23 0.00 |

0.25 0.23 0.23 |

0.25 0.23 0.23 |

1.19 1.19 1.19 |

|

6.000-6.499 |

Under 6 6 to 71/2Over 71/2 |

.013 .010 .020 |

.013 .010 .000 |

.013 .010 .010 |

.013 .010 .010 |

.050 .050 .050 |

152.39-165.08 |

Under 6 6 to 71/2Over 71/2 |

0.33 0.25 0.51 |

0.33 0.25 0.00 |

0.33 0.25 0.25 |

0.33 0.25 0.25 |

1.27 1.27 1.27 |

|

6.500-6.999 |

Under 6 6 to 71/2Over 71/2 |

.015 .012 .023 |

.015 .012 .000 |

.015 .012 .012 |

.015 .012 .012 |

.057 .053 .053 |

165.09-177.78 |

Under 6 6 to 71/2Over 71/2 |

0.38 0.30 0.58 |

0.38 0.30 0.00 |

0.38 0.30 0.30 |

0.38 0.36 0.30 |

1.45 1.35 1.35 |

|

7.000-7.499 |

Under 6 6 to 71/2Over 71/2 |

.018 .013 .026 |

.018 .013 .000 |

.018 .013 .013 |

.018 .013 .013 |

.065 .056 .056 |

177.79-190.48 |

Under 6 6 to 71/2Over 71/2 |

0.46 0.33 0.66 |

0.46 0.33 0.00 |

0.46 0.33 0.33 |

0.46 0.33 0.33 |

1.65 1.42 1.42 |

|

7.500-8.000 |

Under 6 6 to 71/2Over 71/2 |

.020 .015 .030 |

.020 .015 .000 |

.020 .015 .015 |

.020 .015 .015 |

.070 .060 .060 |

190.49-203.20 |

Under 6 6 to 71/2Over 71/2 |

0.51 0.38 0.76 |

0.51 0.38 0.00 |

0.51 0.38 0.38 |

0.51 0.38 0.38 |

1.78 1.52 1.52 |

Cold drawn seamless mechanical tubing---Wall Thickness Tolerances

|

Wall ThicknessPercent of OD |

Maximum Percent Over & Under Nominal |

Wall ThicknessPercent of OD |

Maximum Percent Over & Under Nominal |

||

|

Under 1.499” ID |

1.500” ID & Over |

Under 38.07mm ID |

38.07mm ID & Over |

||

|

Under 10 |

10.0 |

7.5 |

Under 10 |

10.0 |

7.5 |

|

10 to 25 |

10.0 |

6.0 |

10 to 25 |

10.0 |

6.0 |

|

Over 25 |

12.5 |

7.5 |

Over 25 |

12.5 |

7.5 |

Hot-finished seamless mechanical tubing---Diameter Tolerances

|

OD Size Range Inches, Inclusive |

As Rolled or Annealed OD, ± Inches |

Quenched &TemperedOD & ID ± Inches |

OD Size Range mm Inclusive |

As Rolled or Annealed OD, ± mm |

Quenched & TemperedOD & ID ± mm |

|

2.000-2.499 |

.017 |

.027 |

50.80- 63.48 |

0.43 |

0.686 |

|

2.500-2.999 |

.019 |

.029 |

63.49- 76.17 |

0.48 |

0.737 |

|

3.000-3.499 |

.021 |

.032 |

76.18- 88.87 |

0.53 |

0.813 |

|

3.500-3.999 |

.023 |

.035 |

88.88-101.57 |

0.58 |

0.889 |

|

4.000-4.499 |

.025 |

.038 |

101.58-114.28 |

0.64 |

0.965 |

|

4.500-4.999 |

.027 |

.041 |

114.29-126.97 |

0.69 |

1.041 |

|

5.000-5.499 |

.029 |

.044 |

126.98-139.67 |

0.74 |

1.118 |

|

5.500-5.999 |

.031 |

.047 |

139.68-152.38 |

0.79 |

1.194 |

|

6.000-6.499 |

.033 |

.050 |

152.39-165.08 |

0.84 |

1.270 |

|

6.500-6.999 |

.035 |

.053 |

165.09-177.78 |

0.89 |

1.346 |

|

7.000-7.499 |

.037 |

.056 |

177.79-190.48 |

0.94 |

1.422 |

Hot-finished seamless mechanical tubing---Wall Thickness Tolerances

|

Wall ThicknessPercent of OD |

Maximum Percent Over & Under Nominal |

Wall ThicknessPercent of OD |

Maximum Percent Over & Under Nominal |

|

OD 2” and Over |

OD 50.08mm and Over |

||

|

Under 10 10 to 25 |

10.0 7.5 |

Under 10 10 to 25 |

10.0 7.5 |

In structural engineering, the tube is the system where in order to resist lateral loads (wind, seismic, etc.) a building is designed to act like a hollow cylinder, cantilevered perpendicular to the ground.

The system can be constructed using steel, concrete, or composite construction (the discrete use of both steel and concrete). It can be used for office, apartment and mixed-use buildings. Most buildings in excess of 40 stories constructed since the 1960s are of this structural type.